ToughArmor

Ruggedized Removable Drive Enclosures

| Optional Certifications Available for ToughArmor MB991SK-B | |

| TAA | Trade Agreements Act Compliance |

| UL | Safety Standard Certification |

| UL94 | Flammability of Plastic Materials |

| FCC | Federal Communications Commission Compliance |

| Wide Temperature | MIL-STD-810H - Method 501.7 & 502.7 |

| *IEC 60529 (IPX6) | Protection against water jets |

| Series | Model Number | Product Description | Stock Status |

| ExpressCage | MB741SPW-B | 1 x 2.5" SAS/SATA HDD/SSD (15mm) Mobile Rack with Tool-less Installation & ToughCover | Build-to-order |

| MB742SPW-B | 2 x 2.5" SAS/SATA HDD/SSD (9.5mm) Mobile Rack with Tool-less Installation & ToughCover | Build-to-order | |

| ToughArmor | MB092V4KW-B | 2 x U.2/U.3 NVMe SSD (7mm) PCIe 4.0 Mobile Rack with ToughCover (2 x SFF-8654 4i) | Build-to-order |

| MB491SKL-1B | 1 x 2.5” SATA/SAS HDD/SSD (15mm) Mobile Rack with Dual-Lock Design & ToughCover | In-stock | |

| MB492SKW-B | 2 x 2.5” SATA/SAS HDD/SSD (15mm) Mobile Rack with Dual-Lock Design & ToughCover | Build-to-order | |

| MB601V4KW-B | 1 x U.2/U.3 NVMe SSD (15mm) PCIe 4.0 Mobile Rack with ToughCover (1 x SFF-8639) | Build-to-order | |

| MB601M4KW-1B | 1 x M.2 NVMe SSD (2280-22110) PCIe 4.0 Mobile Rack with ToughCover (1 x SFF-8639) | Build-to-order | |

| MB833M4KW-B | 1 x M.2 NVMe SSD (2280-22110) PCIe 4.0 Mobile Rack with ToughCover (1 x SFF-8643) | Build-to-order | |

| MB833M4KW-B V2 | 1 x M.2 NVMe SSD (2280-22110) PCIe 4.0 Mobile Rack with ToughCover (1 x SFF-8654 4i) | Build-to-order | |

| MB834M4KW-B | 2 x M.2 NVMe SSD (2280-22110) PCIe 4.0 Mobile Rack with ToughCover (2 x SFF-8643) | Build-to-order | |

| MB834M4KW-B V2 | 2 x M.2 NVMe SSD (2280-22110) PCIe 4.0 Mobile Rack with ToughCover (2 x SFF-8654 4i) | Build-to-order | |

| MB991IKW-B | 1 x 2.5" SAS/SATA HDD/SSD (15mm) Mobile Rack with ToughCover | Build-to-order | |

| MB991SKW-B | 1 x 2.5" SATA HDD/SSD (15mm) Mobile Rack with ToughCover | Build-to-order | |

| MB992SKW-B | 2 x 2.5” SATA/SAS HDD/SSD (15mm) Mobile Rack with ToughCover | Build-to-order | |

| MB992SKRW-B | 2 x 2.5” SATA HDD/SSD (9.5mm) RAID Mobile Rack with ToughCover (RAID 0/1/BIG/JBOD) | Build-to-order | |

| MB993SKW-B | 3 x 2.5” SAS/SATA HDD/SSD (7mm) Mobile Rack with ToughCover | Build-to-order |

| • |

Rugged heavy duty full metal construction with suggested applications in Imaging, Medical, and Military systems, Media servers, and IPCs, approved & used by Tier 1 companies

|

| • |

Fits 1 x 5mm to 15mm 2.5" SATA / SAS HDD or SSD in external 3.5" drive bay

|

| • |

Rugged heavy Duty Full Metal construction, perfect for enterprise applications

|

| • |

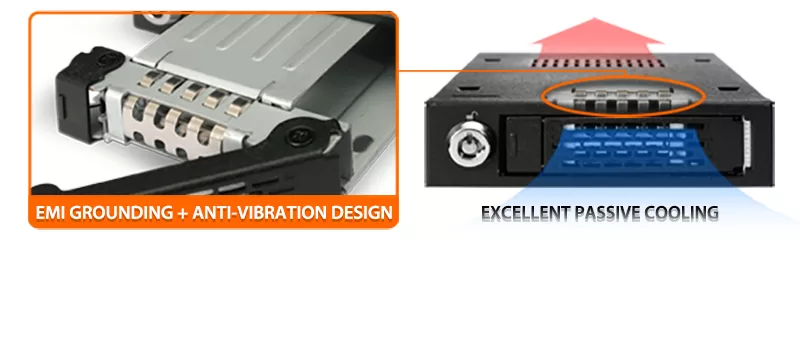

Multi-Flow Technology - provides excellent passive cooling

|

| • |

Anti-Vibration Technology - creates a safe environment for hard drives or SSDs

|

| • |

Active Power Technology (APT) - individual led only powers up if there is drive installed in the drive bay

|

| • |

EMI Grounding – protects hard drives from electrical damage

|

| • |

Eagle-hook lock system & 2-segment safeguard key lock keeps drives secure within the enclosure

|

| • |

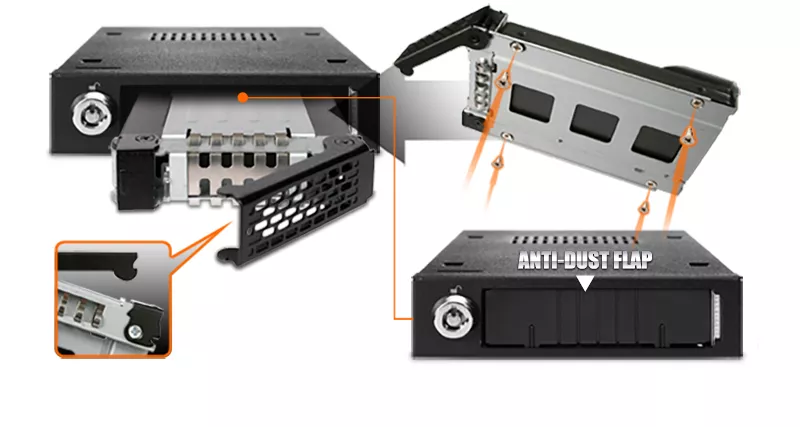

Anti-Dust Flap prevents dust from entering when device not used

|

| • |

Removable EZ Slide Mini Tray system for easy maintenance

|

| • |

Supports SATA 6Gbps / SAS 12Gbps (signle channel)

|

| • |

Single SATA 15 Pin to power entire device

|

| Model Number: | MB991SK-B |

| Color: | Black |

| Support Drive Size: | 2.5" SSD / HDD |

| Compatible Drive Type: | SATA |

| Number of Drives: | 1 |

| Max Drive Height: | 15mm |

| Drive Bay: | 1 x 3.5" floopply drive bay |

| Host Interface: | 1 x SATA 7pin |

| Power Input: | 1 x 15 pin SATA power connector |

| Transfer Rate: | SATA up to 6Gpbs / SAS up to 12Gpbs (depending on hard drive speed) |

| Support HDD Capacity: | No limitation |

| Drive Cooling: | Metal heat dispersion |

| RAID Function: | N/A |

| Structure / Material: | Full metal |

| Support Hot-Swap: | Yes |

| Drive Security: | 2 segment key lock |

| Product Dimension (L x W x H): | 133 x 101.2 x 25.4mm |

| Product Net Weight: | 399g |

| Package Gross Weight: | 454.4g |

| Drive Activity LED Indication: | Drive power: solid green; HDD access: flashing amber |

| Package Contents: | 1 - device, 1 - user manual, 8 - screw, 2 - key |

| SATA Connector Insertion Rate: | 10,000 |

| Humidity: | 5%~65% RH |

| Operating Temperature: | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature: | -35°C to 70°C (-31°F to 158°F) |

| Compliance: | CE, RoHS, REACH |

| Warranty: | 5 years limited warranty |

Compatible Drive Tray (Caddy):

Related Products:

Related Products Series:

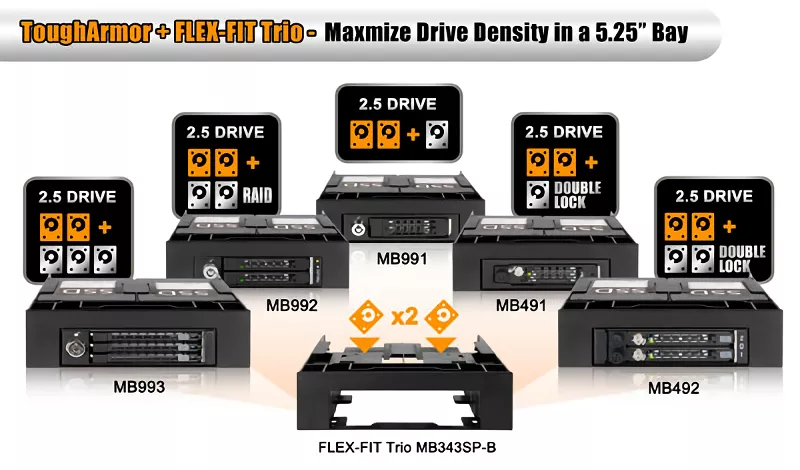

ToughArmor Lineup:

Quick Link:

Q: Does MB991SK-B support the new SATA 3.3 / SAS 3.0 Power Disable feature (PWDIS)?

A: The MB991SK-B does not support the SATA 3.3 / SAS 3.0 PWDIS feature. If you install the SATA/SAS HDD/SSD with PWDIS in MB991SK-B , the drive will not spin, and the system won't detect the drive. See the list below for known SATA/SAS HDD/SSD with the PWDIS feature.

While we recommend to avoid using the SATA/SAS HDD/SSD with PWDIS, you can use the methods below to disable the PWDIS feature physically if you already purchased the drive:

Method 1 – Using the Molex to SATA adapter or cable to disconnect the power to Pin 3 of the SATA power connector.

|

|

|

| Molex to SATA Adapter | Molex to SATA Cable |

Method 2 – Placing Kapton tape on Pin 1-3 of the SATA/SAS power connector to isolate the 3.3V power, as shown below.

|

|

Please contact tech@icydock.com if the problem persists.

Q: I feel that the drive tray's upper and lower metal spring is stuck when inserting the drive tray. What should I do?

A: Remove the drive tray from the enclosure and reinsert the tray without putting excessive pressure on the metal mesh sheet in front of the tray. Excessive force on the front metal mesh sheet may bend the top and bottom metal spring, causing difficulties when inserting the drive tray. Therefore, please do not forcingly insert the drive tray when this happens as it may cause damage to the metal spring.

|

| Please DO NOT put excessive pressure on the metal mesh sheet as shown |

3.5” Mobile Racks for 2.5" SATA/SAS SSD/HDD

With ICY DOCK’s 3.5” drive bay enclosure series, we can maximize the unused 3.5" drive bay of any workstation with an easily removable drive enclosure in the frontal bay. We believe this is critical for most industries that are transitioning to be more efficient, frequently require more drive swap than others, and the ability to transport data from one system to another when drives are in the frontal bay as opposed to being stored internally.